LAR-DH UAV Recovery.

Makes Every Ship a 'MALE UAVs Carrier'.

Advantages: Delivering 300 kgs to 1000km.

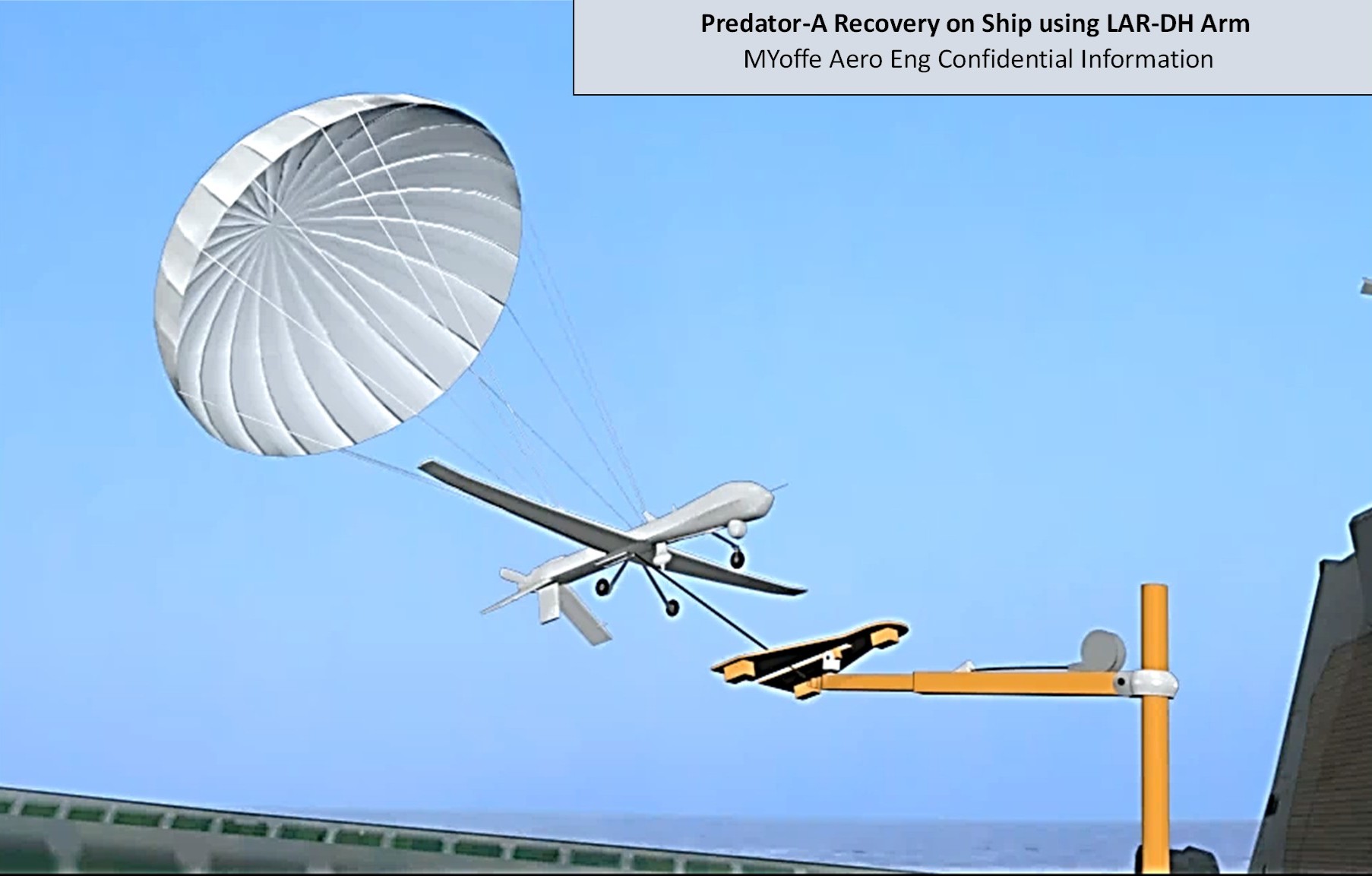

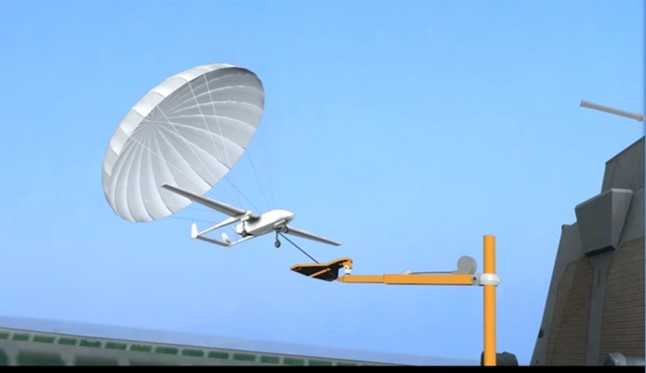

MALE UAV Recovery Cable-Assisted made outside of ship deck

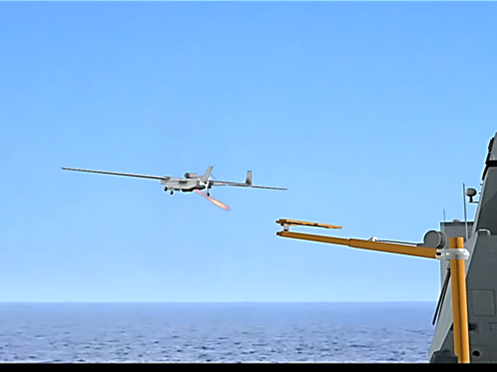

UAV Launching Made From Same Arm

MALE UAV Operation On Frigate

Wing Fold, Hangar

Medium UAV Operation On Patrol Boat

Explanation of air-to-ship recovery solution

The Need

The design goal is to cover whole launch and recovery sequence of larger fixed wing UAVs, to MALE size, on all types of sea vessels, emphasizing safety-securing of UAVs all along on-ship operations. This is made possible by the inherent cable-pull. It covers both aerial pre-recovery maneuvering, the haul-down phase, and post-recovery on-deck moving of the landed UAV - in safety, by computer control, etc. See listing of the method's concept advantages.

Our method is defined as 'Universal Cable-Assisted Point-Recovery Method for Fixed-Wing UAVs onto Ships and Land'. As the definition suggests, a cable is used to haul-to-a-point the recovered air-vehicle [or object]. This mechanically simple principle provides the real point-accuracy - the said cable pulls the UAV/object direct to its outlet. The difficulty is to have the cable connected at both ends, which is addressed and solved by our equipment and detailed flight sequence we design.

The arena of operation at sea has always needed long-enduring aerial surveillance, but this was offered only by large shore-base craft (Catalina, P-3, Atlantique, BAMS) or by aircraft carriers, these becoming scarce, most countries not having even one. All combatants in the arena would benefit from overhead AEW for missile defense, Over The Horizon targeting, and in-Shore targeting. In folded form and size most Fixed-Wing UAVs resemble shipboard missiles in their canisters, thus paving a way to build dedicated shipboard Fixed-Wing UAVs. The only missing link is a method to safely recover those UAVs from the air after a long mission. Our method can achieve just that, so establishing a universal solution and marrying UAVs to ships can start a new family.

Our method can enhance the safety in the recovery of existing land-based systems by its positive-haul-down characteristic. The UAV is accurately forced down by the cable onto its existing landing gear or new cushioning such as a wire-bed or an inflated air cushion. The method uses slow and accurate approach and avoids interference by trees, rocks, bushes or water bodies, regardless of the wind strength and direction changes during the landing procedure. This can virtually eliminate damages to under-belly payloads and UAV systems, even during hard landings.

Our method offers a cable-assisted solution for point-accurate cargo delivery. The solution is insensitive to strong winds and ensures 'Always into the right hands' delivery, as it pulls the load exactly to the center of the drop target ('T'). The only equipment required at the remote unit's site is an improvised 'laundry wire' stretched between two trees, two trucks or two APCs, etc.

Solutions

- Fixed wing UAVs out-of-deck at arm’s tip launch and recovery/mechanical handling to/from stowage on frigates and destroyer (small ships*), no open deck required, up to MALE size;

- Patrol boats/medium UAV simplified installation on congested rear deck;

- L-ships UAV launch and recovery, up to MALE size;

- Land point-accurate recovery in no-runway conditions direct onto an Army truck;

- Forest-clearance launch and recovery with high trees around, 1 Army truck only;

- Precision resupplies delivery (“Always into the Right Hands”) with a ground anchoring point;

- Complete laden UAV point-recovery with a.m. anchor;

- MEDEVAC by a fast UAV, medic optional, direct to a Hospital Ship at sea;

- Supplies/mail delivery on deck of long-range cargo ships at high-seas, up to 1000km/200 kg loads, more;

- Light planes on-an-arm recovery and launch on bigger ships for crew replacing, etc.;

- Sea Range (MSR) Target Drones return back direct to the Launching Ship Deck, avoiding ditching and possible targets sinking, later malfunctions, etc.;

- “Loitering Munition” drones safe “Return Home” even for complex platform shapes (~cruciform) and for armed units;

- ‘Gremlins’-style quick-pace drones launch and recovery from C-130, refueling optional;

- Multiple UAVs operations based on VLU cells;

ADVANTAGES OF THE LAR-DH METHOD’s SOLUTIONS FOR LARGER WINGSPAN UAVs

- Captures the UAV offdeck — does not require special open-deck space for big wings (helipad, flight deck...) — makes many small ships accommodatable to such UAVs.

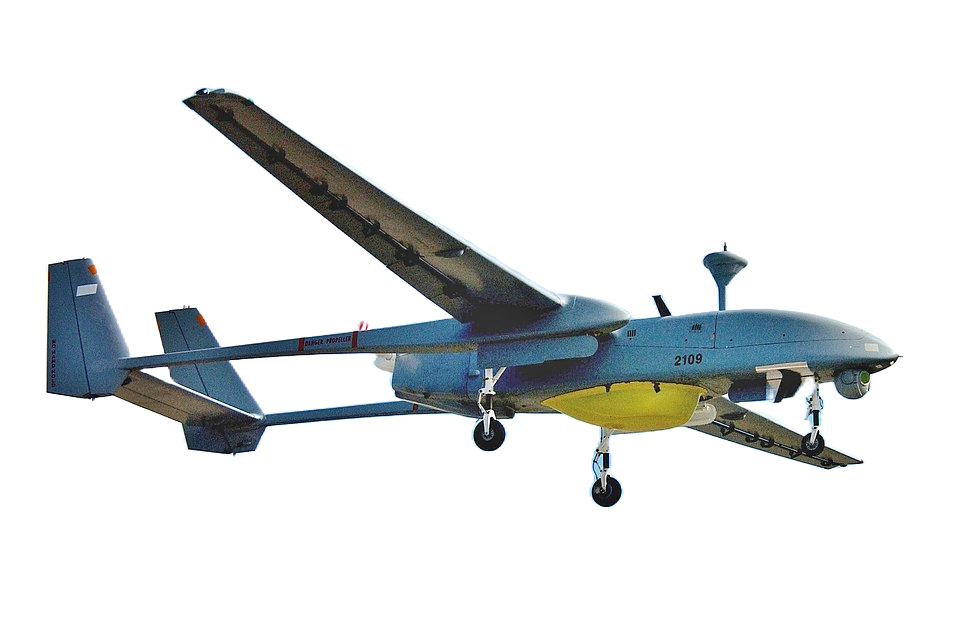

- Suggests modifying existing proven-in-service fixed-wing UAVs – does not require new design.

- Bases on a combination of tried and proven techniques (fly on parachute, folding cranes, USN LAMPS cable-assisted recovery), thus does not require developing complex techniques.

- Provides positive point-accurate touchdown guidance by cable pull even in high sea states, enabling arm’s tip-point capture out of deck in high-state conditions.

- Provides seamless securing on the touchdown, then mechanical transfer to stowage — all the way secure.

- Using same Arm-on-pole for both capturing/recovery and launching is in fact equivalent to VTOLs, even better in 2 aspects: i) The deck footprint for the Arm is less than that for VTOLs’ landing sway in rolling deck conditions; ii) Provides inherent mechanical handling by the Arm = a must for intended MALE UAVs’ weight of >1 ton, easing the tasks on crew.

- Supports the fixed-wing platforms – best in cruise performance, optimal for long range/long endurance missions required at sea; Due to lengthy form — easier to stow than bigger platforms.

Summary:

- “WE MAKE EVERY SMALL SHIP MALE-UAV CARRIER”

- “LAR-DH is: One pole, One arm, One container — and you have the UAV collected and stowed on your ship.”

About Us

Meir Yoffe, Aeronautical Engineer MBA, Experienced UAV Engineer

Meir Yoffe, an aeronautical engineer and inventor, has spent his career shaping aviation and defense technologies. From his early days in the Israeli Air Force Engineering Division, where he was mentored by Abe Karem, the renowned aerospace engineer behind the Predator UAV, to pioneering UAV recovery methods for ships, his innovations have left a lasting impact. He played a key role in the Skyhawk jet-pipe elongation during the Yom Kippur War, contributed to Israel’s first UAV, and patented solutions instrumental in DARPA’s Tern and ONR Side-Arm programs. A private pilot and former lecturer, Yoffe continues to push the boundaries of engineering and creativity.

Contact Us

For more information, reach out to: